A shoe factory is more than just a place where footwear is assembled. It is the heart of creativity, innovation, and precision that brings a brand’s vision to life. Understanding how a shoe factory works can help brands make informed decisions and ensure their products meet the highest standards. In this post, we’ll take you through the entire process — from design to production — highlighting key steps and what to expect.

The Design Phase: From Concept to Prototype

Sketching and Conceptualization

Every shoe starts with an idea. Designers sketch concepts, exploring styles, materials, and functionalities that match the brand’s identity and market trends. This initial phase lays the foundation for what the final product will become.

Creating the First Prototype

Once the design is approved, the factory creates a prototype — a physical sample that showcases the shoe’s shape, materials, and craftsmanship. This prototype is crucial for testing fit, comfort, and aesthetics before mass production begins.

Materials and Sourcing

Selecting Quality Materials

The choice of materials directly impacts the shoe’s durability, comfort, and appearance. Factories work closely with trusted suppliers to source leather, fabrics, soles, and accessories that meet strict quality standards.

Sustainable Sourcing Options

With sustainability becoming a priority, many factories now offer eco-friendly materials and processes. Brands can choose from recycled fabrics, vegetable-tanned leather, and low-impact adhesives to reduce their environmental footprint.

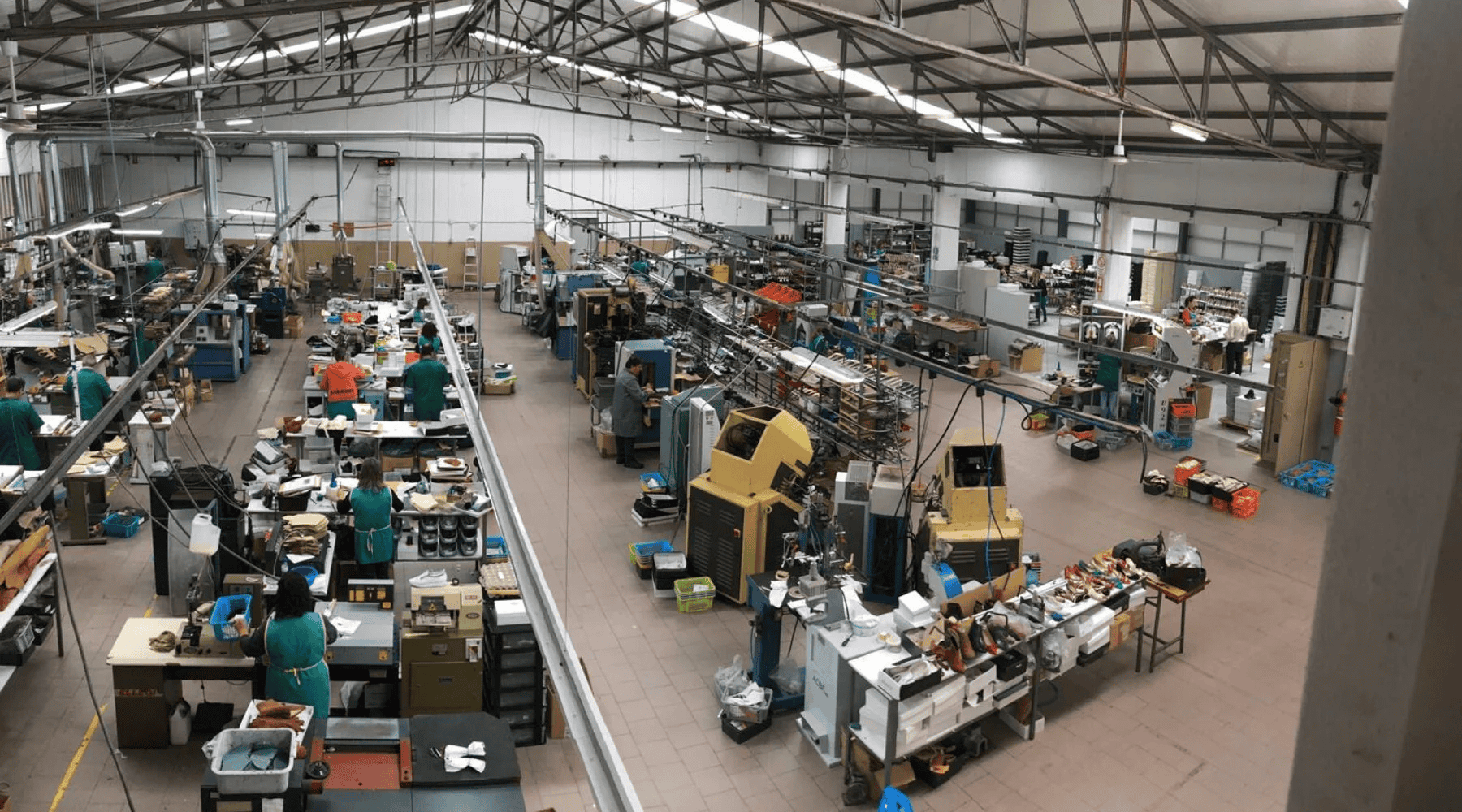

The Footwear Manufacturing Process

Cutting and Sewing

Material sheets are cut precisely according to the design specifications. Skilled workers sew the parts together, ensuring strong seams and accurate alignment.

Assembly and Finishing

The shoe is assembled by combining the upper with the sole, attaching insoles, and adding final touches like eyelets and laces. Quality control checks are performed at every step to maintain high standards.

Quality Control and Testing

Inspection Procedures

Before leaving the factory, each shoe undergoes detailed inspections for defects in stitching, material flaws, and overall construction.

Ensuring Durability and Comfort

Testing may include wear trials, flexibility tests, and resistance to elements like water and abrasion to guarantee the final product meets consumer expectations.

Ready to bring your footwear designs to life with a trusted shoe factory? Contact us today to learn how we can support your brand from concept to finished product!